The nuts and bolts: Together with our customers, we define the goals for the project. These range from the quality and quantity of water, the situation at the installation site and your specifications for the mechanical and electrical equipment.

If several paths lead to the goal, we prepare the different concepts in detail: Investment and operating costs, implementation period, sustainability aspects, etc. The assessment criteria are listed in a comprehensible manner and evaluated in terms of feasibility and cost-effectiveness. Total Cost of Ownership (TCO), Cooperate Carbon Footprint (CCF) and/or Life Cycle Assessment (LCA) are carefully elaborated on a project-specific basis. By jointly considering and weighting the influencing factors, we arrive at the best possible solution.

We can reliably solve over 95% of the applications in industrial water technology “virtually from our desk”. In the few special cases that arise due to the circumstances, such as multiple mixtures of substances with mutually influencing properties or tight tolerances, we develop a solution together with our customers: To this end, we first propose a theoretically promising process or a process combination. A two-stage procedure secures the solution path:

Stage 1

In the laboratory, the basic feasibility is investigated and important parameters such as residence times, treatment chemicals, degradation times are considered. On this basis, initial estimates of investment and operating costs for large-scale application can be made.

Stage 2

An on-site pilot plant on a semi-technical scale secures the chosen path over a longer period of time, even in the event of production-related fluctuations. Important process engineering parameters are varied to ensure transfer to the industrial-scale solution and to optimally design the plant. Neither too small nor too large.

Before implementation, the project usually has to go to the authorities: a permit under water law or a permit under the German Federal Immission Control Act (BImSchG) has to be obtained. We support you around the authority engineering. We prepare the approval documents completely or work to: Process description, PID, layout, environmental concerns. If required, we check the approval and take part in discussions with the authorities.

Yahko Aslan

Head of Engineering

phone: +49 7423 86880 50

yahko.aslan@bws-water.com

What makes us special

- Talk directly to competent project planners who understand your production processes

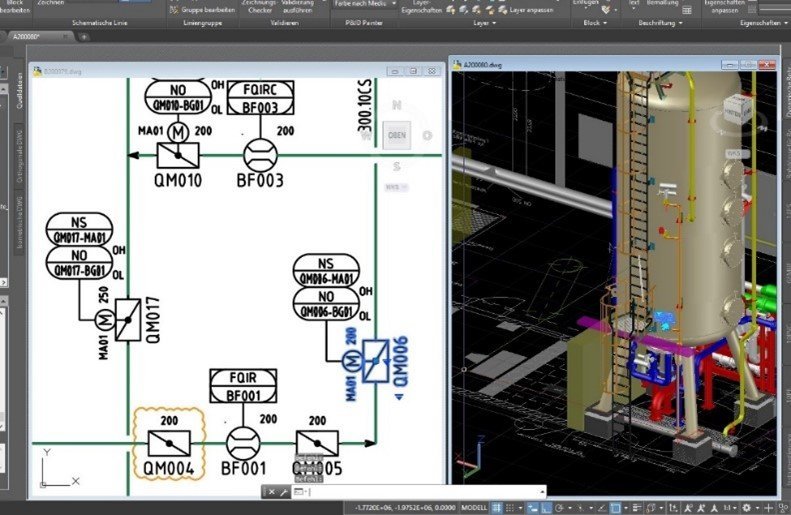

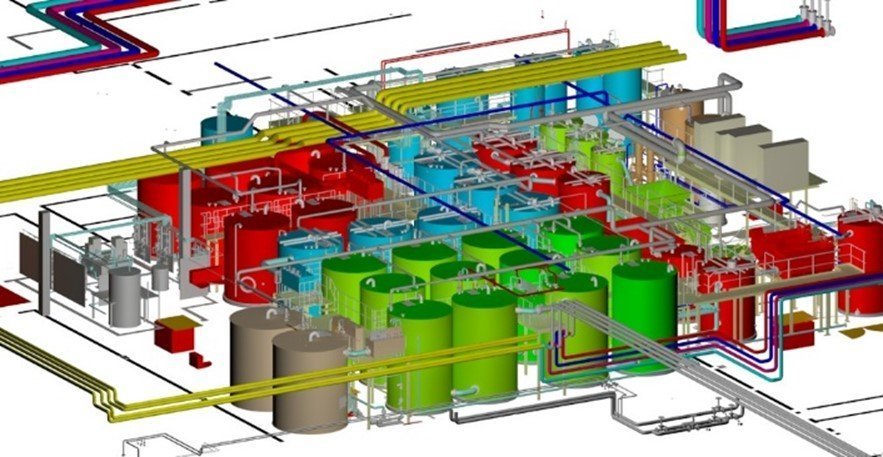

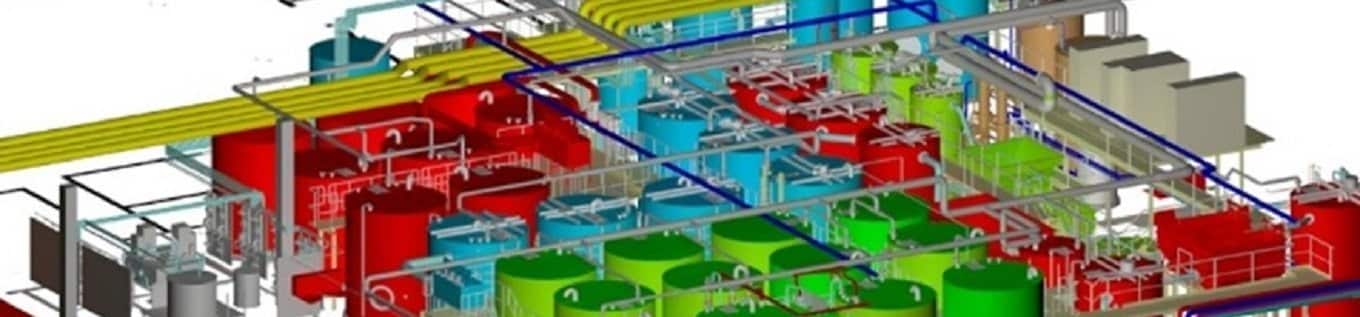

- Identification of potential sources of error through state-of-the-art planning tools

- Optimal process selection – independent and solution-oriented

- Intelligent planning tools

- Cost determination and process optimization through pilot trials

- Up-to-date automation and digitalization