Plant Construction

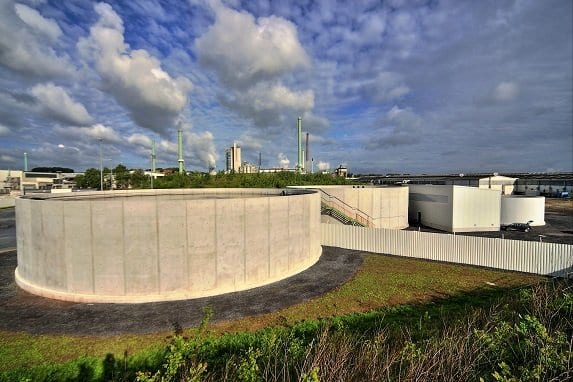

For us, plant construction is the precise intermeshing of process engineering know-how, sound planning and structured project management. Tried and tested installation teams, our own commissioning engineers with expert knowledge, who train your employees and familiarise them with the plant, are elementary components of our philosophy. We will not leave you alone even after the project has been completed. We stay in touch via service and maintenance and help you quickly and unbureaucratically in your day-to-day operations.

Whether in modular design, as a container plant or as an individually designed complete plant, we will meet your requirements and combine the most diverse technologies to create a functioning treatment plant. We regard necessary certifications such as the German WHG as a matter of course.

- Sedimentation and (sand) filtration, de-ironing, demanganisation, desulphurisation

- Activated carbon filter for dechlorination or removal of trace substances

- Softening, deacidification, full desalination

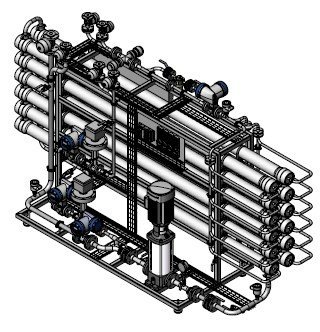

- Ultrafiltration, Nanofiltration and Reverse Osmosis

- Ion exchange process and EDI

Some case studies of realized plants in the field of water treatment:

Drinking water – ultrafiltration – turnkey plant

Turnkey installation of a waterworks with ultrafiltration membranes

Technology & plant characteristics:

Drinking water – ultrafiltration – container plant

Turnkey construction of a waterworks in the factory on the basis of ultrafiltration membranes

Technology & plant characteristics:

Drinking water – filtration – deironing / manganese removal

Planning, delivery, commissioning of a complete waterworks

Technology & plant characteristics:

Beverage industry – reverse osmosis – brew water – water recycling

Wasserreinigungssystem für die Aufbereitung von Konzentrat aus existierenden Umkehr-Osmoseanlagen

Technology & plant characteristics:

Beverage industry – reverse osmosis – brew water – boiler feed water

Reverse osmosis plant for brewing water production with variable adjustment of the brewing water quality via blending

Technology & plant characteristics:

Beverage industry – water degassing – modular plant construction

Planning, delivery and commissioning of a frame stand system ready for connection

Technology & plant characteristics:

University institute – process water – ultra pure water plant – electrodeionisation

Planning, installation and commissioning of an ultra pure water plant for a university institute

Technology & plant characteristics:

- Filtration and conditioning of cooling water

- Disinfection via UV, peroxide or hypochlorite

- Ultrafiltration, nanofiltration, reverse osmosis

- Chemical – physical process water treatment

- Ultrafiltration, Nanofiltration and Reverse Osmosis

- Boiler feed & make-up water

- Circulation systems based on the ion exchanger principle

- Systems for bath care in surface technology

Some case studies of realized plants in the field of process water treatment:

- Reverse Osmosis

- Water Recycling

- Water Recycling

- Ultra Pure Water

- DI-Water

- Wastewater

- Leak Testing

- Washing and Leak Testing

- Washing and Leak Testing

- Cooling Water

- Water Recycling

- Research Project RIKovery

Automotive – process water – reverse osmosis

Production of 5 m³/h demineralised water (permeate) from city water or process water. Use of the permeate as make-up water for the paint shop of the automotive plant.

Technology & plant characteristics:

Automotive – process water – water recycling

Treatment and recycling of wastewater from high-pressure skid cleaning systems at an automobile manufacturer

Technology & plant characteristics:

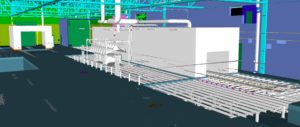

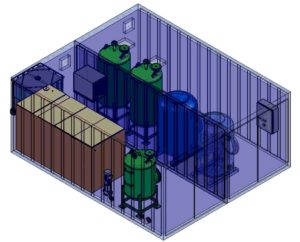

Container-plant – process water – water recycling

Complete plant in modular container design with factory test, delivery, installation and commissioning; plant installed in 2 insulated, heated/air-conditioned container modules

Technology & plant characteristics:

University institute –ultra pure water plant – reverse osmosis – water degassing – mixed bed polisher

Supply, installation and commissioning of a new plant for ultrapure water production for the laboratory

Technology & plant characteristics:

University hospital – process water – DI-water – reverse osmosis

Dismantling of old plant, installation and commissioning of a new plant for DI-water production

Technology & plant characteristics:

Automotive – waste water – chemical-physical treatment – process water

Stepwise renewal of a DI & waste water treatment plant for the paint shop with dismantling of the old plant

Technology & plant characteristics:

Automotive – process water – leak testing (DPA)

Complete delivery, assembly and commissioning of a leak test cabin with spray system and portal dryer as a stand system for final assembled vehicles incl. water treatment at the testing/finishing area for different vehicle types.

Technology & plant characteristics:

Automotive – process water – washing and leak testing (WDPA) with conveyor technology

Delivery, assembly and commissioning of a complete washing and leak testing unit with water treatment for separated washing water and leak testing circuits and transport system at the test/finish area for the electric car production

Technology & plant characteristics:

Automotive – process water – washing and leak testing (WDPA) with conveyor technology

Delivery, assembly and commissioning of a complete washing and leak testing unit with water treatment

Technology & plant characteristics:

Chemical industry – process water – cooling water

Supply, installation and commissioning of a cooling water filtration plant / cooling water purification plant

Technology & plant characteristics:

Process water – wastewater – water recycling – container-plant

Planning and pre-assembly of a complete plant in container module design with factory test, delivery, installation and commissioning: treatment of waste water from the manufacture of medical articles with the aim of reusing the treated water in the production

Technology & plant characteristics:

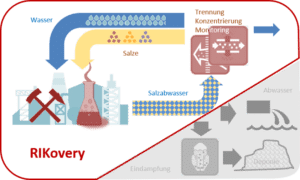

Recycling of industrial saline water by ion separation, concentration and intelligent monitoring

As a research partner, BWS develops economic processes for the treatment of saline production wastewater with the aim of both water and salt recovery.

The project is funded by the Federal Ministry of Education and Research (BMBF). In the project consortium with leading companies from the chemical and alkali industries, universities, research and analytical institutes, BWS is responsible for the plant construction. According to the research results, BWS will develop and build a pilot plant for OARO (= Osmotic Assisted Reverse Osmosis) and HPNF (= High Pressure Nano Filtration). This is to be used for practical tests in industrially relevant applications. On the basis of these results, BWS will carry out a scale-up including a profitability analysis for technical applications.

In order to achieve the goal of reusing salts and water for subsequent processes, specific parameters must be maintained to ensure product quality and operational safety. This is to be achieved in this project through online-capable process monitoring as well as through automated and intelligent data evaluation using existing analytical modules.

More information about this exciting project? Please visit:

- Sedimentation, filtration (sand filter, activated carbon filter etc.)

- Flotation

- Chemical-physical processes for (heavy) metal removal

- Splitting of wastewaters containing hydrocarbons

- Membrane process for the purification of wastewaters containing mineral oil

- Biological wastewater treatment: aerobic or anaerobic processes

- Sludge dewatering via chamber filter presses, belt filters, centrifuges, etc.

- Ion exchanger process

- Removal of trace substances

- Ultrafiltration, nanofiltration, reverse osmosis for further purification of wastewater up to the so-called zero-liquid-discharge (ZLD)

- Evaporator, Evaporator, Desorber

Some case studies of realized plants in the field of wastewater treatment:

- Evaporator

- Ultrafiltration

- Wastewater

- Water Recycling

- Wastewater

- Flotation

- DI-Water

- Wastewater

- Water Recycling

- Reverse Osmosis

Automotive – wastewater – evaporator technology

Treatment of oil-containing waste water, emulsions and washing water from mechanical production, hardening shop and wheel production with oil contents between 1 and 10 %

Technology & plant characteristics:

Automotive – wastewater – chemical-physical treatment – ultrafiltration

Refurbishment/renewal of the waste water plant for the paint shop of an automobile manufacturer with dismantling of the old plant

Technology & plant characteristics:

Automotive – waste water – chemical-physical treatment – process water

Stepwise renewal of a DI & waste water treatment plant for the paint shop with dismantling of the old plant

Technology & plant characteristics:

Process water – wastewater – water recycling – container-plant

Planning and pre-assembly of a complete plant in container module design with factory test, delivery, installation and commissioning: treatment of waste water from the manufacture of medical articles with the aim of reusing the treated water in the production

Technology & plant characteristics:

Paper industry – wastewater – container-plant – biology – water recycling

Biological treatment of process waste water from the paper industry

Technology & plant characteristics:

Life science – wastewater – chemical-physical treatment – dissolved air flotation

Engineering, delivery, commissioning of a wastewater treatment plant for wastewater with high COD content

Technology & plant characteristics:

Automotive – wastewater – chemical-physical treatment – DI-water plant

Engineering, supply, installation and commissioning of a wastewater treatment plant for wastewater from surface finishing

Technology & plant characteristics:

Chemical industry – wastewater – chemical-physical treatment

Installation of an adsorption plant for process wastewater containing mercury including on-site commissioning.

Technology & plant characteristics:

Primary industry – wastewater – chemical-physical treatment – water recycling

Planning, delivery, installation and commissioning of a plant for rainwater retention as well as its treatment and reuse as service water by separating the heavy metal solid particles

Technology & plant characteristics:

Automotive – wastewater – chemical-physical treatment

Retrofitting of 2 reverse osmosis plants for the reduction of COD before discharge into the sewage system after ultrafiltration

Technology & plant characteristics: